Reverse Engineering

Extraction of construction elements from existing components without drawing

Faithfully reproduced

Component: Aluminum impeller

Task: Generation of CAD capable data in STEP format

Procedure:

The first step is to digitize the component using suitable processes. Here we offer a solution in the form of industrial CT, which allows even internal structures to be digitized. The CT data generated is then available as a so-called voxel model.

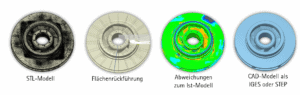

Figure 2: Postprocessing steps on the digital model

Subsequently, the surfaces are generated on the scan data in order to represent the geometry as accurately as possible. At this stage, it is already possible to create a target/actual comparison with an existing model, such as a CAD, and to make initial corrections.

The surface model, which is now available as a point cloud, can then be converted into a polygon mesh and used as an STL model for further processing. In certain cases, an STL model is already sufficient, for example, to manufacture components using additive processes.

For many applications, STL data are not suitable as a basis for further work steps. If desired, we can perform a simple reverse engineering to generate CAD-compatible data formats such as STEP and IGES. This can be further processed in the CAD software.